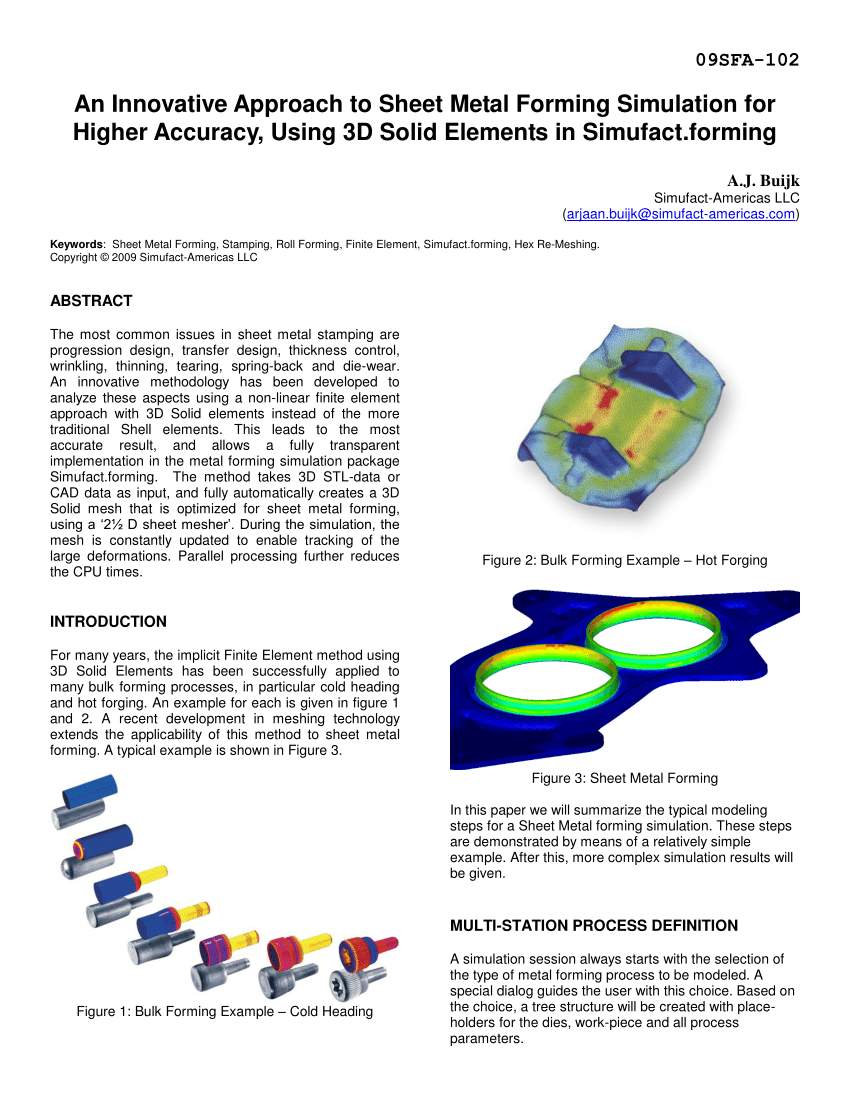

All other factors influencing sheet metal forming we should recall that a sheet metal forming operation can always be from the conceptual point of view.

Sheet metal stamping dies pdf.

Production stamping is generally performed on materials 020 to 080 thick but the process also can be applied to foils as thin as 001 or to plate stock.

Different types of dies.

Metal stamping is a cold forming process that makes use of dies and stamping presses to transform sheet metal into different shapes.

In bending and embossing of sheet metal the female die is replaced with rubber pad rubber pad forming rpf is a metalworking process where sheet metal is pressed between a die and a rubber block made of polyurethane.

Sheet metal stamping stamping presses and stamping dies are tools used to produce high volume sheet metal parts.

In this article i will be exploring the 5 types of dies used in sheet metal operations at respective stages and strokes.

Products made with dies range from simple paper clips to complex pieces used in advanced technology.

Stamping dies are the tools that shape and cut sheet metal parts.

Stamping auto body panels 3 to 5 dies each prototype dies 50 000 production dies 0 75 1 forming dies.

The die set primarily is composed of a punch and a cavity.

Like molds dies are generally customized to the item they are used to create.

These designs are then translated into stamping dies by skilled craftsmen known as diemakers.

Hydro forming cheap tooling no net.

Pieces of flat sheet metal typically referred to as blanks is fed into a sheet metal stamping press that uses a tool and die surface to form the metal into a new shape.

20can pdf deep drawing of drinks cans.

These parts achieve their shape through the effects of the die tooling.

Under pressure the rubber and sheet metal are driven into the die and conform to its shape forming the part.

Download sheet metal stamping dies ebook in pdf epub mobi.

Embossing dies use tension to stretch metal into a shallow depression.

Sheet metal stamping dies also available for read online in mobile and kindle.

They are commonly developed using computer aided design cad software and analytical programs to create and prove out highly accurate unambiguous designs.

Download pdf sheet metal stamping dies book full free.

Once these stamping dies are mounted into presses sheet metal is fed to them.

The metal s thickness and mechanical properties along with the forming punch geometry determine the depth that can be achieved see figure 1.